1.The working principle of magnetic pump

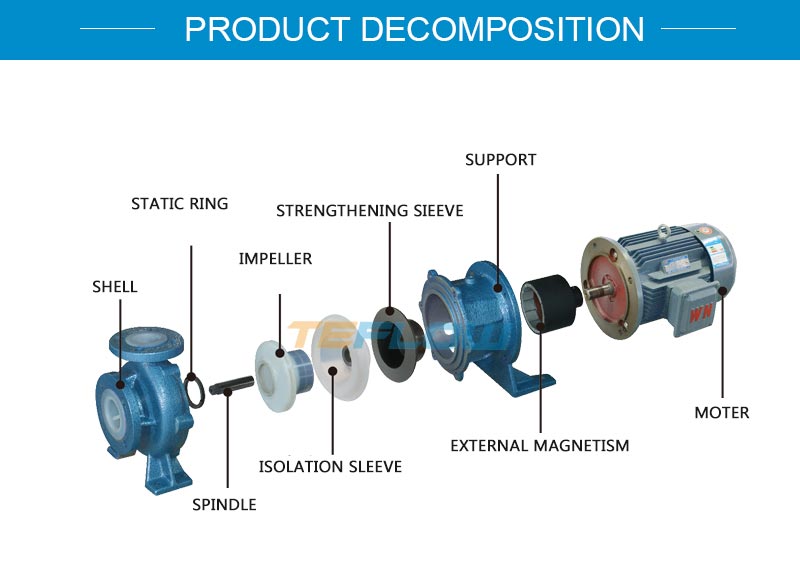

The magnetic pump consists of three parts : pump, magnetic drive and motor. The core component magnetic drive is composed of an external magnetic rotor, an internal magnetic rotor and a non-magnetic isolation sleeve. When the motor drives the external magnetic rotor to rotate, the magnetic field can pass through the air gap and non-magnetic material, drive the internal magnetic rotor connected to the impeller to rotate synchronously, complete the non-contact transmission of power, and transform the dynamic seal into a static seal. Because the pump shaft and the internal magnetic rotor are completely sealed by the pump body and the isolation sleeve, the phenomenon of ' run, run, drip and leakage ' is effectively solved, and the safety problem of flammable, explosive, toxic and harmful medium leakage through pump seal in petrochemical field is reduced.

2.Structural characteristics of magnetic pump

1 ) Internal and external magnetic steel

Under normal operating conditions, there is no aging demagnetization of the magnetic pump over time. However, demagnetization occurs when the pump is overloaded, locked, sliding or the operating temperature is higher than the allowable temperature of the magnetic steel. Therefore, the magnetic pump must operate under normal operating conditions.

2 ) Reinforced sleeve

Non-metallic materials with high resistivity and high strength are used to make the reinforcement sleeve, which can effectively reduce the magnetic eddy current.

3 ) Impeller and ring

The impeller is molded as a whole, and the steel inserts are wrapped inside the fluoroplastic to ensure the strength of the impeller. The mouth ring is generally made of filled polytetrafluoroethylene or silicon carbide material, which is wear-resistant and corrosion-resistant.

4 ) Shell

Made of HT200 lining F46, it can withstand part of the pipeline gravity.

5 ) Base

HT200 integral casting was adopted, and the upper and lower parts were flattened by gantry milling machine, which ensured the level and stability of fluoroplastic magnetic pump.

6 ) Sliding bearings

Tetrafluoro filled graphite, carbon fiber material, wear and corrosion resistance.

3.Magnetic pump use attention

1 ) Ferromagnetic impurities and hard impurities are not allowed in the medium transported by the magnetic pump. If there are ferromagnetic particles, a magnetic filter is required.

2 ) Not allowed to work at less than 30 % rated flow.

3 ) For the transmission medium density is greater than 1400kg / m3 liquid, need to inform our company sales department, magnetic coupling needs to be designed separately.

4 ) The conveying suction pressure ( inlet pressure ) is not more than 0.2 MPa, and the upper limit working pressure is 1.0 MPa.

5 ) The standard magnetic pump has a temperature resistance of 100 °C. If the temperature exceeds 100 °C, the unit will not operate normally, and the high temperature resistant magnetic steel must be replaced.

+86 18130251359

+86 18130251359 teflowpumps@tlpumps.com

teflowpumps@tlpumps.com

+86+0563-5093318

+86+0563-5093318